Our Capabilities

In order to ensure we can maintain our quality and remain cost competitive, we have established several divisions in our facilities to maximise efficiency.

We utilise state of the art water processing and filtration technologies in our facility. Natural mineral water extracted from underground goes through several crucial steps of media filtration processes to remove excessive minerals while preserving the optimum taste for the final product. Subsequent processes include the usage of ultra-fine filtration methods to eliminate all unwanted impurities in the treated water. These specific steps ensure that the water in each bottle is as natural as possible. As for our drinking (R.O.) water, a different filtration method called Reverse Osmosis is used. By applying high pressure on the filtration membrane, pure water is filtered through the membrane except for the minerals. This process helps us to produce the water that is crystal clear and purest in taste.

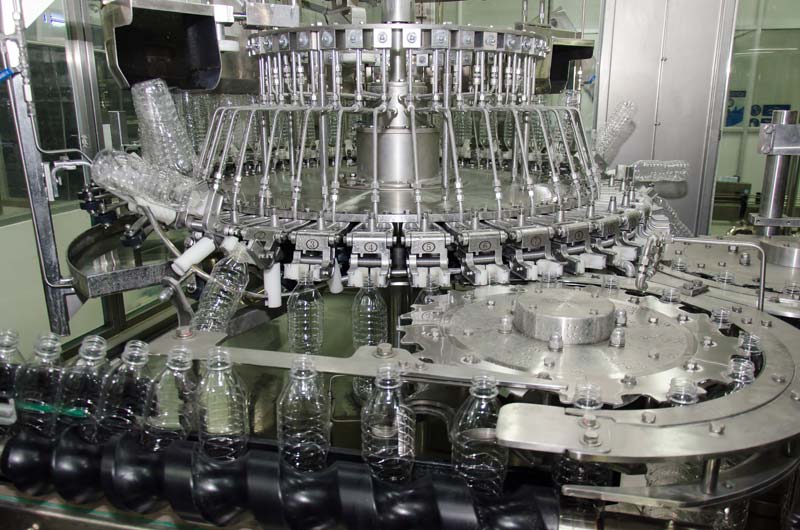

To ensure efficient bottling, we have invested in machinery from overseas which helps us to minimise rejects while maintaining zero contact from the elements. We are always on the search for better and more efficient machines to ensure that our products remain competitive in the markets. As of the moment in 2016, our most efficient production line could bottle up to 18,000 bottles per hour.

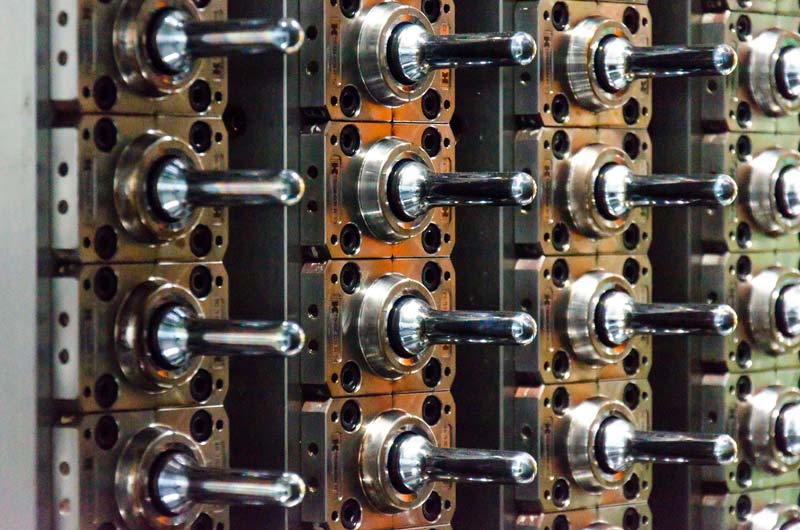

The clarity and safety of each bottle is of utmost importance to us. In order for us to have high quality, clear bottles, we have made sure of that by producing them ourselves. The injection machines produce preforms which are strictly inspected by our qualified engineers. The preforms are then passed to the bottle blowing division to be made into bottles. Our most capable machine can now produce 4 bottles per second.

While all air compressors may function the same, Oil-Free ones ensure that the output air which blows the bottles is virtually free from any mechanical contact which include grease and dust. This not only helps us produce the clearest of bottles, but also crucially the cleanest of bottles.

We have robust Quality Control (QC) and Quality Assurance (QA) teams to inspect and maintain the high quality standards that we strongly believe in. They are passionate in their line of work and are also trained professionally to be efficient and effective.